The 3300 Hydraulic Drill Rig

The 3300 Hydraulic Drill Rig is designed for challenging environments where compactness and power are both critical. This versatile rig is adaptable to a wide range of carriers, including trucks, 4×4 agricultural tractors, tracked vehicles, and modular skid mounts, making it ideal for helicopter or barge transport. Whether in rugged terrains or remote locations, the 3300 delivers the power and flexibility needed for deep drilling operations.

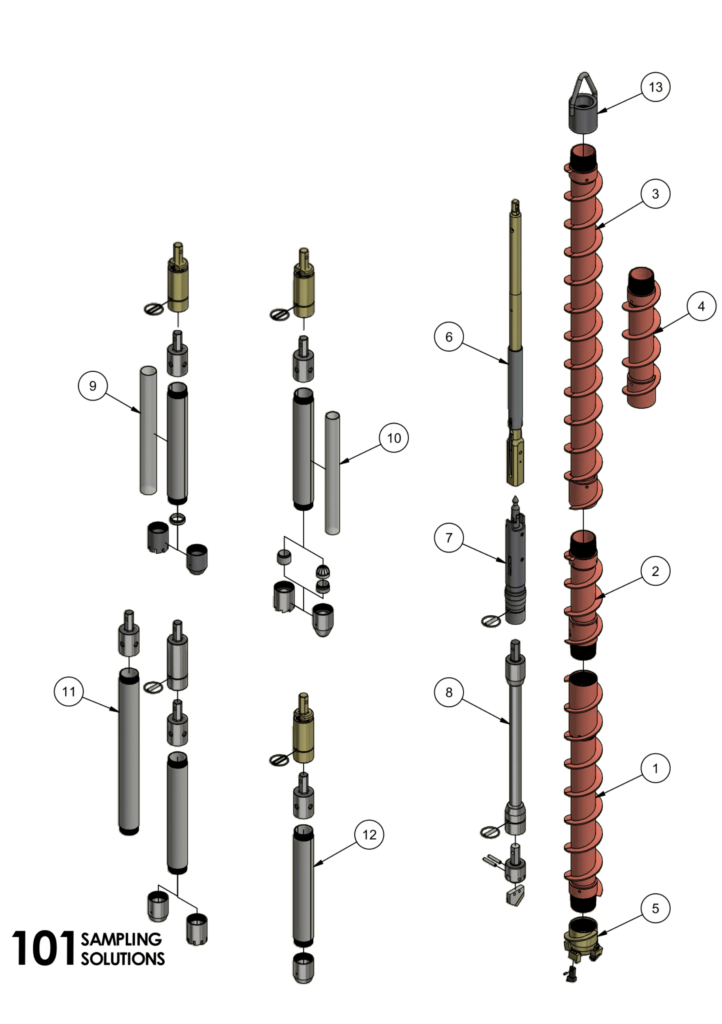

Capabilities of the 3300 Hydraulic Drill Rig:

- Solid and Hollow Auger Drilling

- Diamond Drilling

- Rotary Air Blast (RAB) Drilling

- Mud Circulation Drilling

- Reverse Circulation (RC) Drilling

Base 3300 Drill Specifications:

Drilling Depths:

-

- NQ Core Drilling: Up to 250 meters

- 4” Open Hole: Up to 120 meters

- 6” OD Augers: Up to 20 meters

Note: Drilling depths are based on a clean, straight, fluid-filled vertical hole. Actual depths may vary depending on ground conditions and operator efficiency.

Features:

- Standard channel RHS mounting

- Standard surface finish

- Fixed fluid line and valve (no swivels)

- Remote throttle and stop

Applications:

The multipurpose 3300 Drill is suitable for a wide range of applications, including but not limited to:

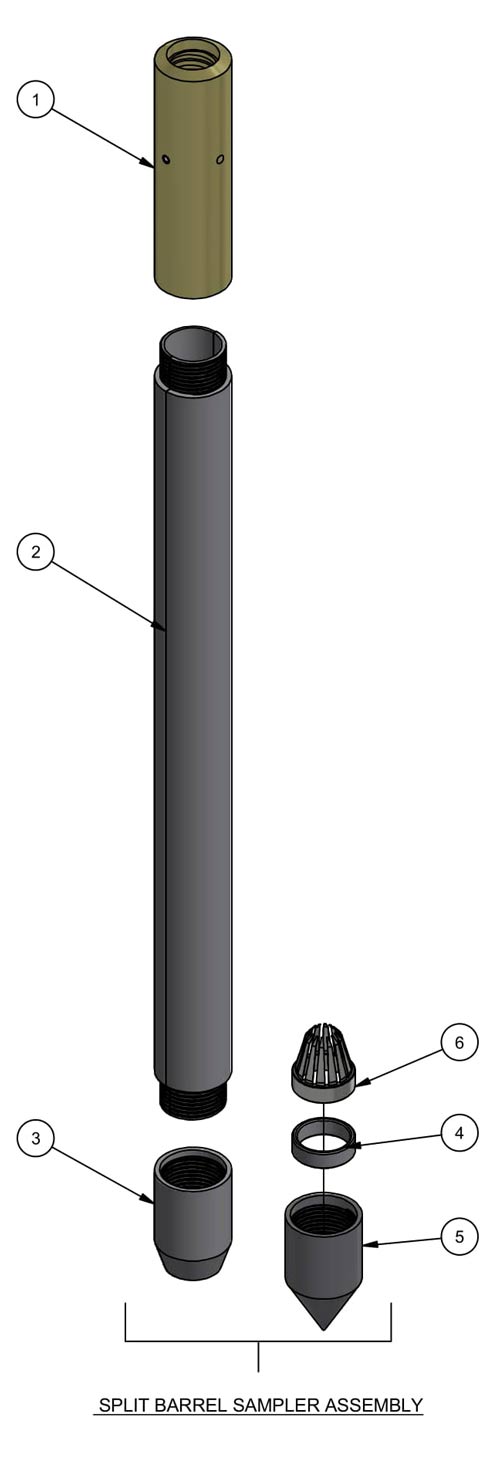

- Geotechnical sampling: The 3300 Drill is ideal for geotechnical sampling tasks, including using augers, conventional coring (NMLC), wireline coring, or wash boring to obtain soil samples. Its compact design combined with increased power allows for deeper drilling, making it well-suited for Standard Penetration Testing (SPT).

- Environmental sampling: This drill is excellent for collecting deeper or larger diameter environmental samples. Its small footprint and powerful capabilities enable a broad range of sampling tasks with minimal disturbance to the surrounding area.

- Mineral exploration: The 3300 Drill is well-suited for mineral exploration, capable of handling various drilling methods such as diamond drilling, Rotary Air Blast (RAB), and Reverse Circulation (RC). Its versatility and ease of configuration changes make it a cost-effective solution for mineral sampling.

- Water wells: The drill’s ability to handle large fluid volumes and its compact size make it ideal for drilling water wells, especially in areas with difficult access. It can be configured with a side entry swivel or a large diameter fluid swivel, making it effective for deeper and larger diameter wells.

Options and Tooling:

- 500 Kg wireline winch and extension to give 6.5 under the sheaves

- 2,000 Kg winch, brake and extension

- Hydraulic head slide

- Simple Angle drilling frame

- Tower dump and cradle

- Fully encased levelling jacks and valving

- Hydraulic assist Rod Breakout

- Diamond speed motor up to 1,000 Rpm and fittings

- Two speed head

- Oil cooler and fittings

- FMC EO4 piston pump 61 L/m at 38 bar with speed control

- Injection pump Silvan AS71 hose, fittings and plumbing

- Swing up operator’s platform

- Additional Pull out up to 5,200 kg depending on engine selection

- Engines up to 90 hp for extra torque and pull out

- Truck tray

- Tandem trailer

- Heli portable kit

- Tracks